HACCP Software: Contaminations, Food Safety Management and ISO 22000!

Our HACCP web software guides the multi-disciplinary group through the various stages of the HACCP food production quality control method and allows you to guarantee quality and compliance within the framework of ISO 22000-2018 or IFS. It is deployed in Food Industry, in the Life Science sector (cosmetics, pharmaceuticals, etc.) and in water treatment services.

Fully meets the business requirements of the digitalization in Industry 4.0 and the constraints of information systems departments.

Knowllence’s team of training consultants can guide you through traing sessions, the software, its configuration and the conduct of your first HACCP studies.

HACCP Web: The Smart Solution for Food and Water Industries

Our HACCP software is available in a standard version or fully customized for the food industry and water services.

It can also be tailored to meet the specific needs of other sectors, including catering, primary agriculture, and more.

Why digitize your HACCP records and documentation?

For the quality manager and his team, it is essential to have all his HACCP records and documentation at hand since they are essential elements for the quality in manufacturing.

Benefits include:

- Capture, structure and ensure the consistency of data (from definition to design – industrialization and manufacturing) throughout risk analysis and formalized surveillance/monitoring

- Save time during meetings (in facilitation) and for updates

- Modular tools to help you comply with ISO 22000 or private IFS – BRC standard

- Capitalize on your know-how with dynamic, cumulative models

- Transfer your analysis and non-conformity information to your client’s studies

- Ensuring all data traceability (not just at document level)

- Integrate with your information system: management of action plans, for example with Action Facilitator, Management of non-compliance, for example with TEEXMA for Quality, use of data from measuring instruments for pre-packed products with Check Prod (ERELIA ), SPC/MES, etc.).

- Manage the activities of the project team in charge of HACCP analyses, provide indicators, and automatically generate summary documents and statistics.

- Capture events in the field, report them to expert teams and manage their resolution.

- Harness the power of full traceability to correct errors in HACCP testing/analysis and monitoring with the Storyboard function.

- Involving international teams and reducing language/vocabulary errors by using multilingual content libraries.

- Secure your audits (ISO client, internal, etc.) by having an HACCP system that is constantly up to date.

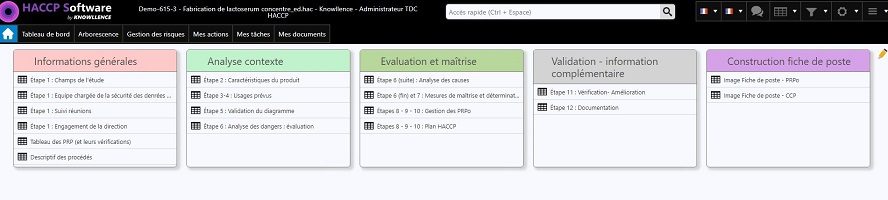

Welcome portal for carrying out the 12 steps of HACCP

The software guides you through the HACCP process, and structures all the relevant data, making it easier for the various team members to take ownership.

- Assembling a team who have specific knowledge and expertise about the product and process.

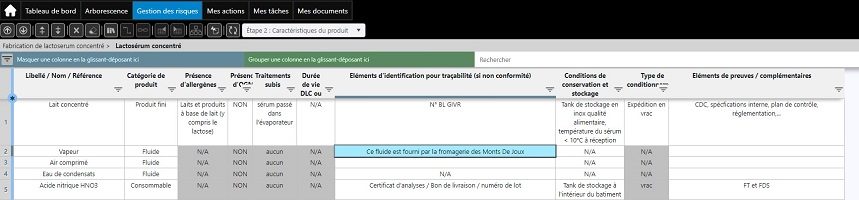

- Describe the Product.

- Identify the Intended Use and Consumers.

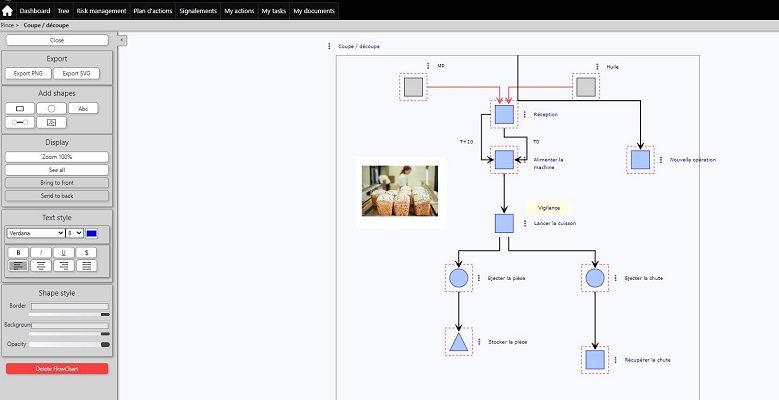

- Construct Flow chart (or production diagram).

- Description of process steps and control measures.

- Conduct a Hazard Analysis and identify appropriate control measures.

- Hazard Assessment.

- Determine Critical Control Points (CCPs).

- Establish of operational programs.

- Establish Corrective Actions HACCP plan.

- Validation of control measures.

- Documentation and Record Keeping, Audit Planning.

As well as centralizing all the information resulting from the workgroup reports, the HACCP software offers a range of data entry forms that can be filled in as your meetings progress:

- First, organization of the decision tree (CCPs) for your plan.

- After the flow diagram representing your manufacturing process: operations, inputs, outputs, etc.

- Then, the Hazard Analysis tables for recording and analyzing the danger leading to setting up action plans and process monitoring plan.

To describe the different dangers, users can use shared content libraries, which they can of course complete and improve if they have the rights to do so.

The HACCP web software automatically generates manufacturing documents: HACCP summary document, action plan, etc.

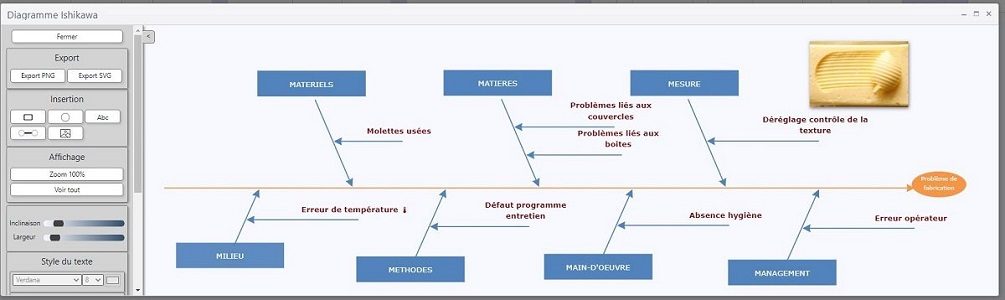

Of course, it also includes various graphic formatting tools to help the working group and facilitate communication. For example, you can easily create a CCP decision tree or an Ishikawa Diagram:

Example of a fishbone diagram for cause-and-effect research

HACCP Software: Is it Worth it?

After finishing your teams training program in the principles of requirements of HACCP and ISO 22000, to ensure that the best practices taught are firmly and effectively used, it is essential to have a pragmatic software that enables everyone to play their part in Food Safety and process Quality on a daily basis, which facilitates feedback and manages continuous improvement plans.

The improved rigor of the HACCP approach and the tracking of actions thanks to the software is encourage our customers to use the method. This allows them to be ready for all types of audits (client, ISO, internal, etc.) and therefore significantly improve their image in an increasingly demanding environment.

Finally, food safety failure is very costly, not just in the cost to human life. HACCP and food safety systems are a sound business investment. Brand damage and company reputation are hard to put a price on.

What is HACCP software for the food industry ?

HACCP software for the food industry is a digital solution that allows management of all food safety procedures according to the HACCP principles (Hazard Analysis Critical Control Point).

It simplifies the management of critical control points (CCPs), product traceability, quality record tracking, and audit preparation.

By digitalizing these processes, food industry professionals gain greater responsiveness, reliability, and regulatory compliance, while reducing risks associated with manual errors or missed entries.

Why digitize your HACCP plan in the food industry ?

Digitizing your HACCP plan is a key driver of performance and compliance.

Industrial HACCP software enables you to:

- Automate quality and temperature checks via connected sensors.

- Centralize all data (cleaning records, self-inspections, non-conformities).

- Generate audit reports with a single click for inspections and certifications (IFS, BRC, ISO 22000).

- Ensure full traceability from raw materials to finished products.

It is a strategic tool to modernize food safety management and maintain a high level of regulatory compliance.

How do you choose the right HACCP software for your production site ?

The choice of HACCP software depends on your industrial process and quality requirements.

Here are the key criteria to consider :

- Regulatory compliance (Hygiene Package, ISO 22000, IFS, BRC).

- User-friendliness and ease of use for your on-site teams.

- IoT compatibility (sensors, scales, data loggers).

- Dashboards and automated alerts for real-time monitoring.

- Secure hosting and responsive technical support.

A good HACCP software should integrate seamlessly into your quality system and serve as a daily management tool for food safety.

Is HACCP software mandatory for food industry companies ?

No, HACCP software is not legally required, but implementing a HACCP plan is mandatory for all food industry companies.

However, using a digital solution helps simplify compliance, reduce the risk of non-conformities, and streamline audits.

In practice, more and more food manufacturers are adopting HACCP software as a guarantee of compliance, traceability, and operational performance. Today, it has become a major competitive advantage in a sector subject to increasingly strict food safety requirements.