A great opportunity for the automotive industry & complex systems

In June 2019, the USA-based AIAG and the German VDA published a handbook with an aligned, structured approach for both methodologies during the FMEA development process. The goal of correlating these FMEA methods was to make working with subcontractors easier and to control the cost of quality (COQ).

The new AIAG & VDA FMEA Handbook opens up new opportunities for the auto industry and complex systems. The manual updates the classic FMEA methods and the best practices to apply.

What does the AIAG & VDA FMEA Handbook method do?

FMEA means Failure Mode and Effects Analysis. FMEA implementation guarantees that all potential problems have been taken into consideration and that they are managed by applying actions to the product (Design FMEA) or the manufacturing process (Process FMEA). It is a tool to ensure quality in design and production.

The AIAG & VDA FMEA Handbook approach has seven steps:

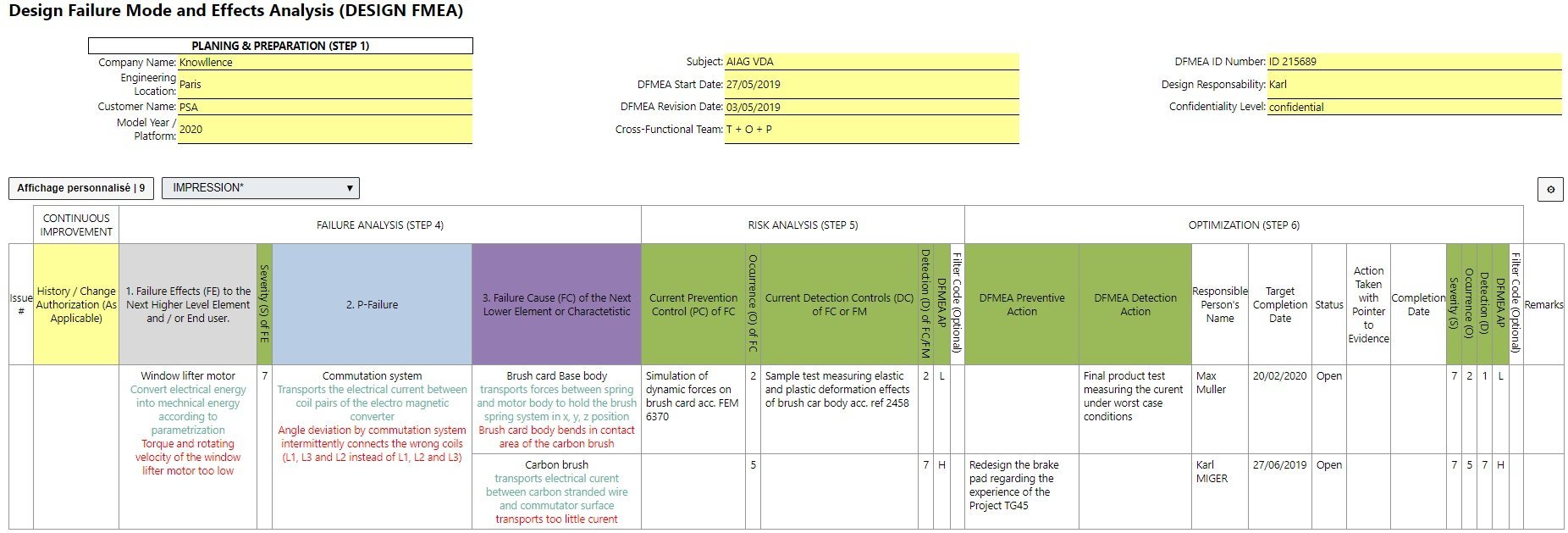

Step 1: Planning and Preparation of the Project

The first step is to prepare the FMEA scope for the studied system. This step includes:

- Identifying the project: Updating the report headings

- Satisfying the 5 Ts: InTent, Timing, Team, Tasks, and Tools

- Defining the scope and the boundaries of the FMEA analysis

- Prioritizing the functions, systems, and process operations

We have developed an interface dedicated to “How to prioritize your fmea” in partnership with EURO-SYMBIOSE.

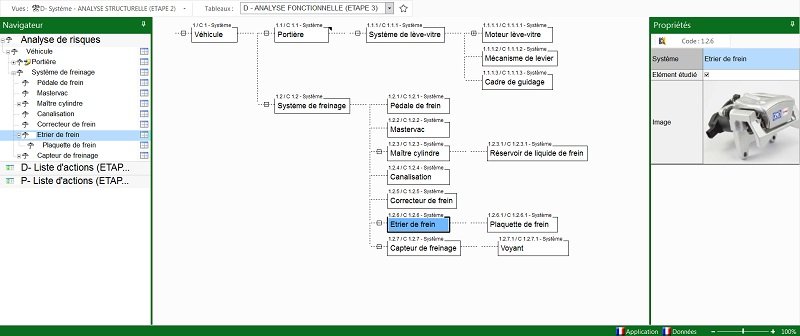

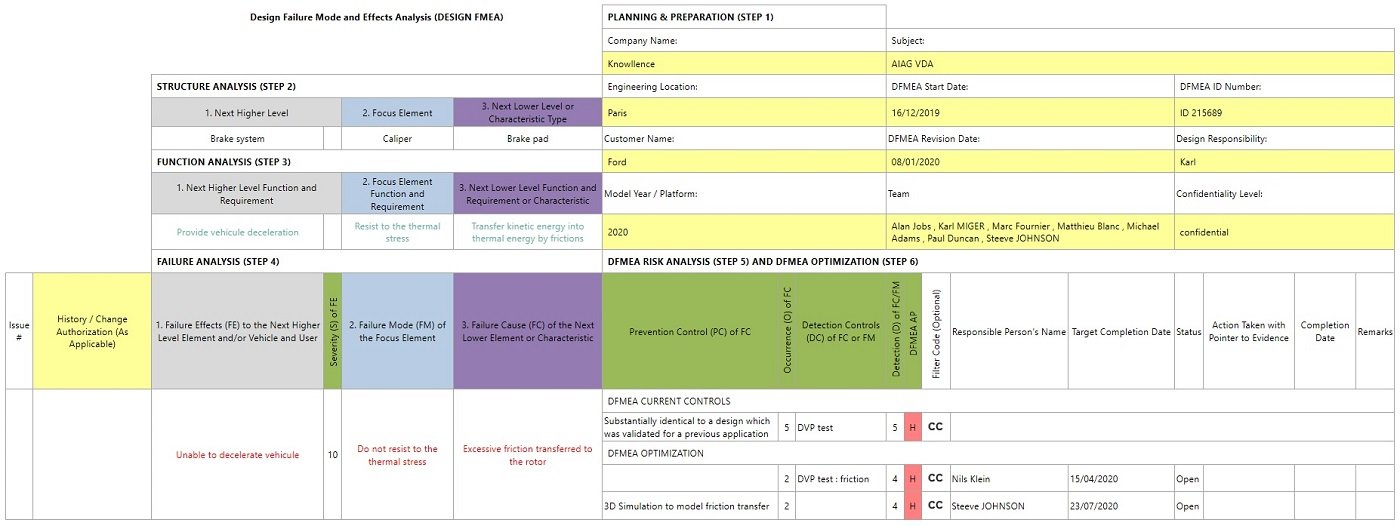

Step 2: Structure Analysis

Step 2 involves breaking down the tree into system, subsystem, and component elements. It includes:

- Breaking down the product nomenclature. Structure analysis can be performed by the tree tool or by the block boundary diagram.

- Breaking down the tree

- Identifying the studied element(s)

- Creating the Design/Process links

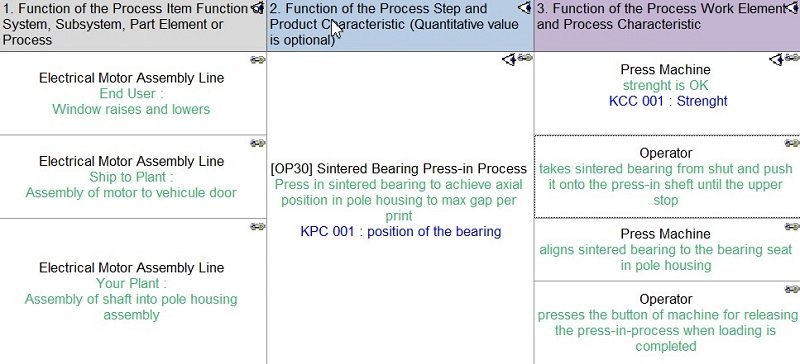

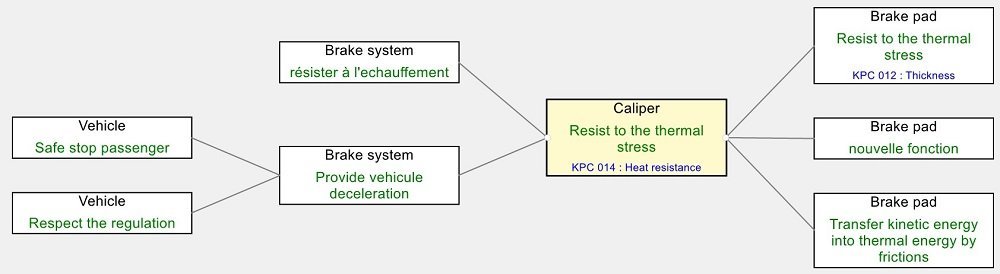

Step 3: Function Analysis

This step identifies the functions carried out by the structural elements. It includes:

-

- Identifying and defining the functions (the functional analysis using the NEED Program)

- Integrating the functional analysis of the Process

- Creating the tree or function network through a functional block diagram

- Linking the requirements or characteristics to the functions

- Defining the functional links through a network and being able to show that your customers’ requirements are covered

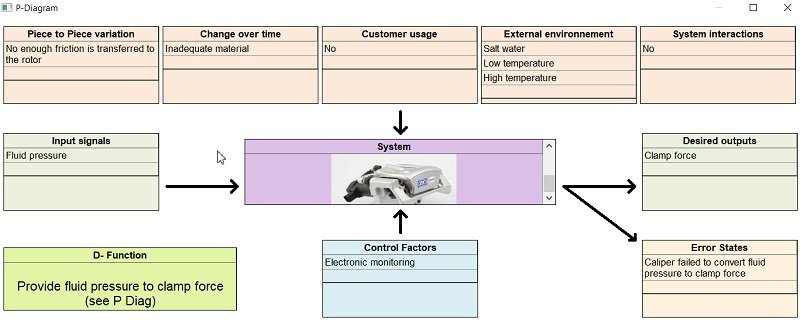

The brainstorming mode lets you open a Parameter Diagram (P-Diagram) for each function.

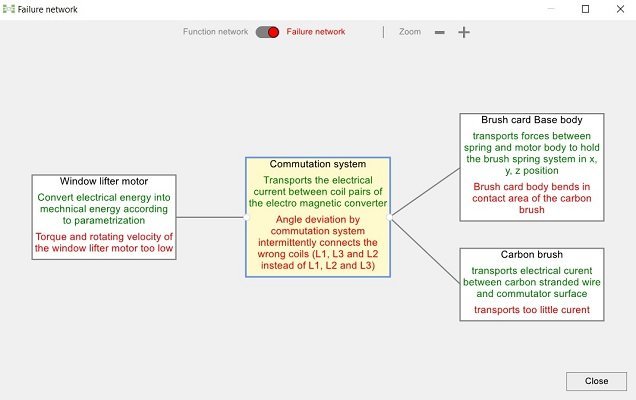

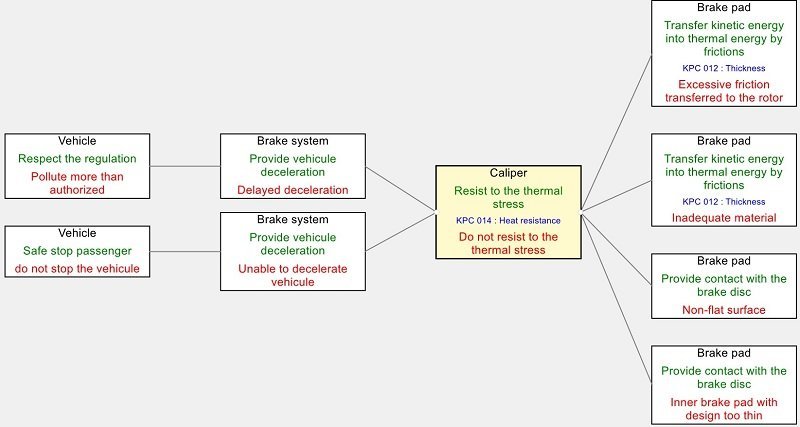

Step 4: Failure Analysis

This step in the AIAG & VDA FMEA Handbook describes all of the potential risks by taking into account:

- An itemization of failures through functional analysis deductions

- A coherent look at failures beginning at the characteristics of each component up to their effects on the upstream system. This coherence is ensured by the failure chain.

- Connections between Design FMEA and Process FMEA

- A coherence of severities throughout the entire analysis

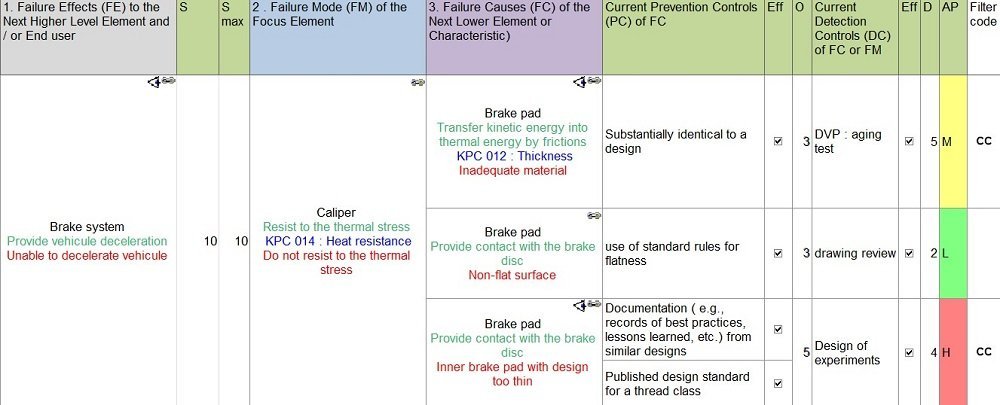

Step 5: Risk Analysis

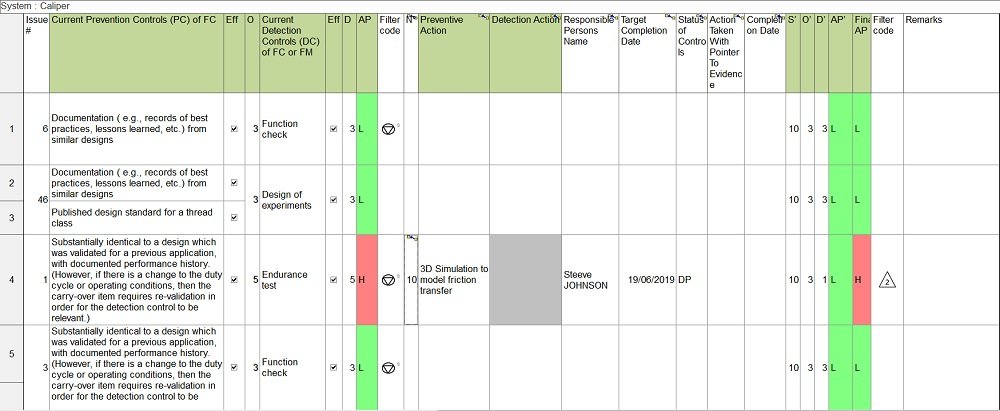

Step 5 in the AIAG & VDA FMEA Handbook involves checking the existing detection or prevention criteria and scoring severity, occurrence, and detection. It includes:

- Identifying the existing prevention and detection criteria

- Assigning scores for severity, occurrence, and detection

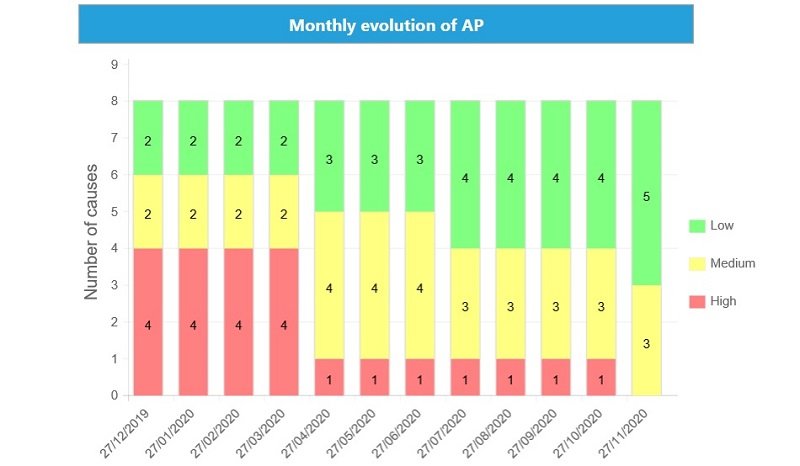

- Evaluating the AP matrix (Action Priority)

Step 6: Optimization

The purpose of Step 6 is to determine and schedule the actions needed to lower risk either by reducing the frequency of causes or by improving the ability to detect the causes or modes of failures. It includes:

- Scheduling actions to reduce the current risks

- Designating someone to be responsible for the action who is in charge of seeing it carried out

- Setting a deadline for the action to be completed

- Defining the projected scores for occurrence and detection

Step 7: Documentation of Results

This step allows automatic generation of reports in formats proposed under the standard to:

- Disclose the status of actions and the current risks

- Reveal the actions implemented and how well they worked

- Present the results and conclusions of the FMEA analysis

The Essence of the AIAG & VDA FMEA Handbook

The bottom line is a common approach to requirements and best practices so that subcontractors have a single FMEA process. By correlating tools and methods to produce robust, precise, and complete FMEA studies, the needs and expectations of customers can be fully met. The ambitious handbook:

- Combines and simplifies in one single document the recommendations that are the same on both sides of the Atlantic, even if customer specific requirements (CSR) still prevail – Reverse FMEA for Renault and PSA, for example.

- Better defines risk evaluation rules and helps in decision-making. The scoring tables have been redone with new criteria that can now be personalized. Action Priority (AP) has replaced the Risk Priority Number (RPN).

- Integrates a system dimension and takes into account the special features for onboard electronics. A whole new chapter is entirely dedicated to this third FMEA type, which supplements Design FMEAs using FMEA-MSRs (Monitoring and System Responses).

What will be the impacts of the AIAG & VDA FMEA approach for our customers?

Our FMEA software has already integrated the current recommendations with respect to new parameters as a complement to the regular version of our applications (AIAG 4th Edition). The new features for Design FMEAs and Process FMEAs have been available since July 2019. They were updated with changes at the end of that year. FMEA-MSRs will be available soon.

Our software comes in French, English, and German from the get-go.

For more information

To use this approach, you’ll need to bring your teams’ skills and the software parameters up to speed.

Knowllence proposes global solutions with:

- An audit of your situation

- Training in the new AIAG & VDA FMEA methodology and parameters

- Transformation and implementation of compliance for the affected FMEA studies, with the understanding this concerns only FMEA studies linked to new and generic projects.

If you already have the software and do not want to implement the new, aligned approach, Knowllence will still maintain your current parameters (AIAG 4th Edition or personalized).

Where can you find the standards for the new AIAG & VDA FMEA Handbook method?

Versions of this handbook are available at the following links:

- In French: https://euro-symbiose.fr/actualites/le-guide-amdec-aiag-vda-est-disponible-en-francais

- In English: https://www.aiag.org/store/quality/publications

- In German: https://www.vda-qmc.de/en/publications/yellow-prints

Handbooks in other languages will be released gradually.