As a part of our partnership with EURO-SYMBIOSE, the FMEA experts of our two companies worked together in order to warrant you a common understanding of the new AIAG-VDA handbook and to synchronize our best practices.

The FMEA software by Knowllence is customized to be in perfect match with the EURO-SYMBIOSE training and assistance. The goal if of course to facilitate the deployment by our Clients.

Training and software are both available in french and english, the best way to harminize practices on a worldwide scale.

The FMEA practice

Over the years, the FMEA (Failure Mode, Effects and Criticality Analysis) practice imposed itself to all industrial sectors, in order to develop reliable & robust products and manufacturing processes, by meeting the predefined functional requirements, customer specifications and by reducing the costs.

The process always starts with the breakdown of a product or a process. On the Design side, the product can be analyzed from a functional point of view or through its technical specifications. On the Process side, the approach consists in starting from the process synoptic and identifying all the manufacturing & control operations.

However, the efficiency of the approach could face with issues due to the significant scope of the analysis. Quickly, the FMEA team becomes aware of the volume of work and sometimes becomes discouraged. We are then tempted to fill in the lines with copy and paste and the analysis goes wrong and loses all its added value for the project.

This difficulty of the approach generally results from a lack of organization to carry out the FMEAs in the project phase and keep them up to date during the life of the product. The following questions should be considered :

- What are the resources allocated to the achievement of FMEA ?

- How can we take advantage of previous projects and generic FMEA ?

- On which project item we should work in priority? How to prioritize the analysis?

- How to manage the FMEA practice ?

The new FMEA AIAG-VDA manual

The new FMEA AIAG-VDA manual aims at a more robust FMEA methodology to manage the associated risks associated with products and manufacturing processes, taking into account the complexity of multiple regulatory and Equipment Manufacturer specific requirements as well as the demanding expectations of consumers for more innovative products.

The new FMEA AIAG-VDA manual improves the approach by breaking down the analysis into 7 steps, from planning to documenting the results. The new FMEA AIAG-VDA manual includes more specificities in the Severity (S), Occurrence (O) and Detection (D) rating criteria. For example, confirmation of the effectiveness of current prevention and detection measures, product and process feedback, as well as the maturity of the detection method are now included in the rating criteria.

In addition, the « Priority for Action » (PA) index replaces the RPN index (Risk Priority Number). The S, O and D ratings individually and in combination for the determination of risk reduction actions are prioritized: High, Medium or Low.

The FMEA prioritization tool

In addition to the « Priority for Action » defined in the AIAG-VDA harmonized manual for the automotive sector, EURO-SYMBIOSE and KNOWLLENCE have developed a tool that is simple and quick to implement to help to prioritize the implementation steps of one FMEA (prioritization table).

EURO-SYMBIOSE and KNOWLLENCE have been working together since September 2019 to propose efficient global solutions. Thus, the FMEA software proposed by KNOWLLENCE has been customized to be in perfect adequacy with the method taught during EURO-SYMBIOSE’s trainings and coaching missions.

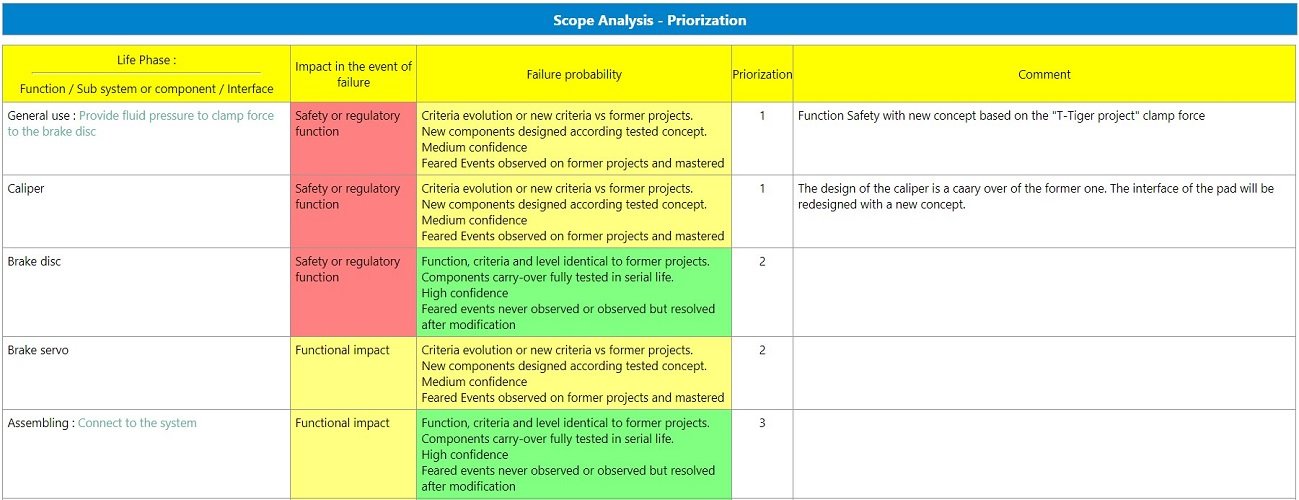

Focus on the prioritization of FMEAs :

On the side of the FMEA Product,

- the prioritization can be carried out following the functional analysis of the need and / or following the technical breakdown of the bill of material. Depending on the choice of the project manager, these options can be combined or not. The two prioritization criteria are the impact in case of failure taking into account the return of experience from other projects.

-

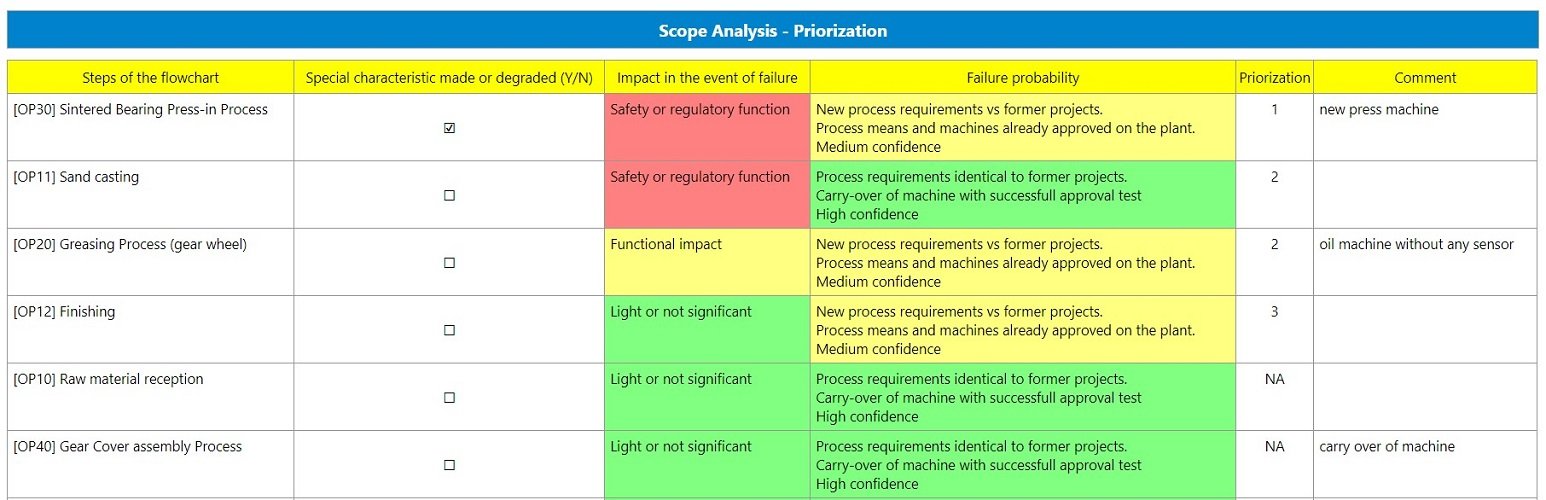

On the FMEA Process side,

the approach is structured according to the process flow chart. The analysis takes into account of (i) the fulfillment or the degradation of special characteristics at each stage of the process, (ii) the impacts in case of failure and (iii) the probability of failure.

The advantages of this prioritization tool :

- A single session allows you to define analysis priorities.

- In the event of an audit, this tool will help justify why certain parts of the project (component, function or process stage) have not been covered. A report can be edited to provide the justification taken at the beginning by the project team.

- This preliminary analysis allows to highlight the chosen scope of study, to set a course for the team members and to maintain the level of motivation.

EURO-SYMBIOSE supports its customers in their search for efficiency and improvement of their performances for more than 30 years with Consulting, Audit & Training services. To discover the trainings and coaching/facilitator solutions in the hand-on implementation of FMEA within your company: click here. For more information, contact us at 02 51 13 13 00 or send an email to muriel.gueret@euro-symbiose.fr.

To purchase the new FMEA AIAG-VDA manual in French, click here.

KNOWLLENCE, software publisher in the field of risk control and design methodologies, has a recognized experience and competence in particular in the implementation of FMEA solutions. Discover the FMEA software by participating to a 30 minutes demonstration by clicking here.