Our previous software what we had, no longer met the demands of our automotive customers and its interface was aging. Knowllence Robust Engineering Software makes it possible to meet our customers cross-functional requirement for strict application of the AIAG-VDA standard FMEA.

It also allows to respond our digitalization strategy. The web interface is much simpler, and the HTML file extracts save time on the points to be checked.

What is your current job duties and key responsibilities?

I am in charge of the automotive division management system. My responsibilities cover 15 factories (about 3200 people) in Europe, America and China.

The chosen organization is to have a FMEA expert for the division, who acts as a referent for the 2 to 4 FMEA pilots at each site.

The number of FMEA studies is not an indicator that we monitor, but we can say that there are around 80 in Delle, and 300 in Germany at present. Design represents about 30% of the projects, the rest is in processes.

Our customers are either OEM car manufacturers (Stellantis, Daimler, Ford, etc.) or Tier 1S (ZF, Forvia, Hitachi, TI Automotive, etc.) and some other industries (Schneider, etc.).

I’m responsible for controlling operating methods and providing support for the deployment of certain digital tools.

I’ve been told about your 4.0 approach; can you tell me more about it?

We are constantly looking for solutions that will enable us to be more agile, productive and efficient. Digitization makes it easier to make data available, analyze discrepancies and limit human error.

You previously had another software: why did you abandon it?

We previously had software that did not allow us to make our operating methods efficient in terms of strict compliance with AIAG & VDA standards.

It no longer met the increasing demands of our automotive customers, particularly in terms of legal formalism and consolidation of actions. What’s more, the interface was outdated, and although it was a SaaS solution, it was not accessible via a web browser.

Why did you choose our Robust Engineering Software?

Knowllence Robust Engineering Software makes it possible to meet our customers cross-functional requirement for strict application of the AIAG-VDA standard FMEA. It also allows to respond our digitalization strategy: This solution ensures consistency between Functional Analysis, Product FMEA, Process FMEA, monitoring plan and data at the operator’s workstation.

The web interface is much simpler, and the HTML file extracts save time on the points to be checked. For example, thanks to the multiple filters in the HTML report, it’s easy to highlight only the critical characteristics for a quick “check”.

What does Robust Engineering Software offer you that you didn’t have before?

First and foremost, strict compliance with the new AIAG/VDA method. It avoids redundancies in data entry and therefore facilitates updating.

How did you go the API development with your MES solution?

The development of the API between Knowllence’s tool and our MES (Manufacturing Execution System) solution was fast and efficient thanks to communication and collegial work with the Knowllence teams and our MES provider/ supplier.

What does it bring you?

Via this interface, we have succeeded in providing the operator with coherent, usable data for monitoring the product and process parameters. The operator now has direct access to data from the latest update of the FMEA and the monitoring plan.

No more paper to update, with the risk of data entry errors.

How did the implementation phases/deployment with Knowllence go?

The implementation and deployment in progress is going rather smoothly thanks to constant support from the Knowllence teams as the process progresses.

What perimeter is currently covered?

Automotive because there was pressure from our customers to switch to the new AIAG/VDA version.

We have begun deploying the tool in France, and will soon be rolling it out in Germany, Spain and the Czech Republic. Use is planned in French, German and Spanish, with an English interface for the Czech Republic.

The Aerospace Division is interested in the tool and Knowllence has already been chosen as its risk management tool. It is currently being tested on one site.

Why choose SaaS (cloud) hosting?

SaaS is a well-known solution, which is easier for our IT teams to manage (maintenance, data security, etc.) and offers greater flexibility of use floating licenses.

How satisfied are you with the software and with Knowllence?

The software now covers all the points we wanted to improve. The relationship with the Knowllence teams is very good. They are always ready and willing to listen to our needs in terms of organization or software improvements.

Is there anything else you’d like to highlight?

Robust Engineering Software, proposed by Knowllence, remains a technical tool that needs to be approached with a good understanding of the FMEA AIAG/VDA and Control Plan methods, but the construction of the tool makes it possible to respect and enforce compliance with these methodologies. This is really important to standardize operating modes for all our collaborators/employees. The home page is a real plus. It’s a really practical entry point, allowing you to quickly find your way around the studies, and go straight to the place you’re looking for.

Find out more

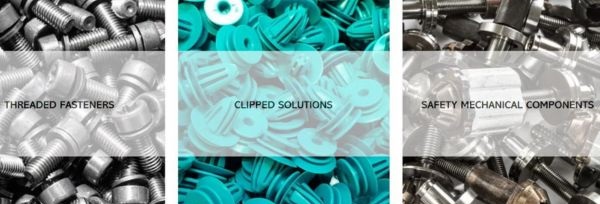

Innovating since 1777, LISI AUTOMOTIVE is an international family enterprise specialized in the design and production of quick-fastening automotive assembly solutions and safety-critical components.

Recognized as a reliable, innovative and expert supplier, LISI AUTOMOTIVE contributes to the development of tomorrow’s vehicles by helping to improve the safety, comfort, environmental impact and ease of assembly of the products manufactured by its clients.

Discover LISI AUTOMOTIVE…