Découvrez FMEA en moins de 4 minutes !

Logiciel Amdec Produit (Design FMEA) et AMDEC Process (Process FMEA)

Le logiciel AMDEC qui structure et capitalise vraiment vos études AMDEC !

Module de Robust Engineering Software

Etudes AMDEC Produit, Moyen, Process, APR, la vue « risque du système »

plans de surveillance, diagramme de flux, fiches de postes, caractéristiques spéciales.

Un logiciel AMDEC standard et personnalisable

Le logiciel FMEA de Robust Engineering Software propose de gérer les différentes études de risques AMDEC au sein de la même licence logicielle : AMDEC Produit, AMDEC Process, DRBFM, diagrammes de flux / synoptiques de fabrication, plans de surveillance, plans d’actions, fiches de poste, et caractéristiques spéciales.

On peut choisir de ne dérouler qu’un type d’AMDEC (par ex AMDEC Produit) ou d’enchaîner de façon intégrée et cohérente l’AMDEC Produit / Process au sein de la même étude avec propagation et suivi des CS (caractéristiques spéciales), cotations associées, etc.

Le logiciel vous propose des référentiels normalisés :

- les classiques AIAG FMEA 4th (2009) ou VDA 4

- ou récent AIAG-VDA 2019, voir l’alignement AIAG-VDA ou nos webinaires.

Ce logiciel AMDEC peut intégralement être personnalisé à vos habitudes et méthodes de travail , autant au niveau de l’interface de saisie (tableaux, seuils, cotations,…) qu’au niveau des documents et indicateurs liés aux AMDEC.

Le logiciel AMDEC de Knowllence est disponible dans de nombreuses langues, grâce à la gestion multilingue, vous pouvez en outre gérer chacune de vos données et de vos bibliothèques dans autant de langues que nécessaire, y compris chinois, polonais, tchèque, etc.

Cohérence et partage de toutes les données autour de l’AMDEC

La cohérence des données et documents est assurée par le partage des connaissances au sein d’une base de données unique entre les différents outils tout au long du processus de conception et d’industrialisation, du produit jusqu’au process :

- Au sein du logiciel AMDEC « FMEA » : entre AMDEC Produit, DRBFM, AMDEC Process, Plan de Surveillance, Diagramme de Flux, et Caractéristiques Spéciales,

- Avec les modules complémentaires de conception d’Analyses fonctionnelles dans Robust Engineering Software afin de conduire une étude AMDEC méthodologiquement « juste » et complète, le logiciel AMDEC FMEA partage les données pertinentes sur le besoin,

- Les statistiques d’occurrence process et les liaisons avec les causes de dysfonctionnement peuvent être récupérées de votre solution de gestion des non-conformités ou de suivi de production (SPC / MSP) pour enrichir les études AMDEC Process (connecteur dynamique).

Gains de temps et ROI sur les AMDEC

Nos clients témoignent qu’ils obtiennent un retour d’investissement rapide avec le logiciel AMDEC FMEA : des gains significatifs de temps (jusqu’à 50%) dans la réalisation de leurs études AMDEC, dans les 10 mois après la formation au logiciel.

Le logiciel AMDEC permet aussi de disposer d’un support de travail commun, facilitant la communication entre les différentes équipes intervenant sur le projet : R&D, qualité, BE, indus, production, maintenance – et marketing si les risques produits identifiés impactent le business.

Grâce au logiciel et à la méthode AMDEC, l’amélioration de la rigueur dans les projets favorise une meilleure implication de tous, et devient un véritable outil de productivité, permettant d’améliorer considérablement l’image vis-à-vis de clients de plus en plus exigeants.

Le logiciel FMEA permet le pilotage opérationnel des plans d’actions via des indicateurs, des documents html dynamiques et des E-mails d’informations et de relance.

Les études AMDEC sont donc structurées, standardisées et uniformisées pour l’ensemble de l’entreprise et des équipes projet, ce qui permet une meilleure efficacité, une réutilisation facilitée, et une cohérence des livrables destinés à vos clients.

Les éléments arborescents sont affichés avec un code couleur (modifiable) en fonction des seuils de criticité. Vous pouvez ainsi instantanément cibler les points à travailler prioritairement, et vous inscrire dans un raisonnement Lean.

L’outil de priorisation (disponible uniquement en AIAG-VDA) permet également aux équipes de prioriser l’analyse de risque et de se concentrer sur les composants/opérations les plus critiques. Le gain de temps est notable !

Capitalisation: bibliothèques et génériques AMDEC

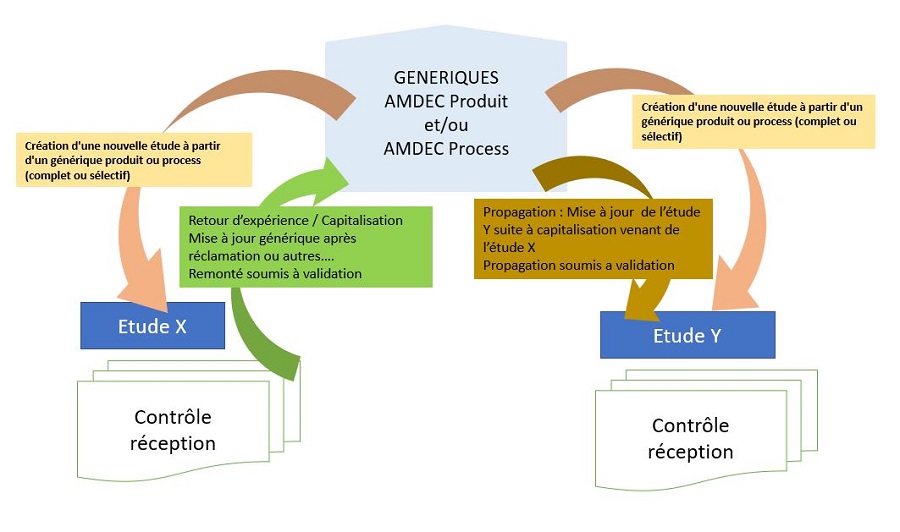

Le logiciel AMDEC FMEA de Knowllence permet de créer des AMDEC génériques cumulatifs, qui s’enrichiront au fur et à mesure des nouveaux projets et dont les modifications seront faciles à propager sur les projets en cours.

Le concept est de s’affranchir du nom des études ou des projets antérieurs qui sont trop nombreux, en structurant toute l’expérience cumulée dans une seule base (générique + bibliothèques).

Lors de la création d’une nouvelle étude, il sera possible de choisir les fonctions, les constituants, les opérations process depuis ce générique pour construire la nouvelle étude.

Vous pourrez ainsi aisément créer des référentiels et gérer vos savoir-faire au sein de votre entreprise, ceci n’étant pérenne et fiable que grâce à la gestion de la traçabilité sur chacune des données : vous saurez identifier par un simple clic droit l’origine de la donnée concernée, et donc décider de son intégration (ou non) dans votre projet.

- Vous pouvez constituer autant de bibliothèques d’effets, modes, causes, moyens de prévention, etc., que nécessaires, ces bibliothèques sont liées entre elles et permettent ensuite de vous proposer simplement les modes de défaillances habituellement liés à un type de fonction/composant, de même que les causes habituellement associées à un mode de défaillance, etc. Vos études exploitent ainsi toujours le même vocabulaire technique et la rigueur est facilitée par ces propositions, dans toutes les langues de travail nécessaires,

- Vous pouvez bien sûr à tout moment compléter, enrichir ces bibliothèques – si vous en avez les droits.

- Vous pouvez créer des études complètes à partir d’AMDEC génériques Produit et Process, avec tous les liens déjà déclarés entre les 2. Vous pouvez aussi choisir d’intégrer des éléments génériques tableau par tableau pour constituer une étude générique complète.

- Après avoir formalisé des modifications ou des ajouts (incident, 8D,…) dans un générique, vous pouvez choisir de les répercuter / propager vers les études concernées et donc de garantir leur prise en compte systématique.

Vous pouvez donc gérer vos référentiels d’entreprise de façon dynamique, et continue, sous le contrôle du garant qui pourra valider les connaissances avant leur diffusion. On contribue ainsi à votre stratégie de Knowledge Management.

Pilotage des plans d’actions

Le logiciel FMEA contribue à la mise en place de l’usine numérique dématérialisée :

- Le logiciel AMDEC offre un suivi aisé des actions avec un système de filtre en un clic souris, de documents de communication, d’indicateurs et d’alertes E-mail d’information et de relance.

- Ce système de gestion des actions est centralisé soit dans le logiciel (rapport multi-études), soit dans notre outil transversal Action Facilitator, soit dans votre système de gestion de plan d’actions d’entreprise (connecteur dynamique).

- Le logiciel AMDEC permet de propager les actions identifiées suite à un incident ou un problème avéré, du générique vers toutes les références de produits similaires concernés, le pilote AMDEC maîtrisant le choix de cette propagation.

- La liste des actions est disponible en excel, en pdf et en html : triée par responsable, état d’action ou délai. Le format html permet en outre de filtrer et de trier sur les statuts d’actions, les responsables, les délais, etc.

- Les documents html bénéficient de tous les avantages liés à un navigateur comme Chrome : traduction automatique…

Gestion des plans de surveillance (Control Plan)

Etant gérés au sein de la même base et partageant les mêmes données, les plans de surveillance sont gérés en cohérence avec l’AMDEC Process et les caractéristiques produit. Vous pouvez aussi choisir de créer les surveillances, les caractéristiques à partir de la détection de l’AMDEC Process.

Cela permet d’éviter les écarts entre AMDEC Process et Plan de surveillance, et donc de limiter les risques de non-conformités lors des audits.

Ces plans de surveillance peuvent être gérés au niveau prototype, présérie, production série, renforcé et/ou interne.

Pour en savoir plus sur les plans de surveillance de notre logiciel AMDEC…

Suivi des caractéristiques spéciales

Grâce à la centralisation dans une base de données, FMEA permet le suivi de l’ensemble des caractéristiques critiques : depuis les critères des fonctions, des caractéristiques de composants et les paramètres des opérations process. FMEA garantit également la cohérence et la propagation de la cotation des effets associés aux caractéristiques spéciales ou critiques.

Pour en savoir plus sur la gestion des caractéristiques spéciales avec le logiciel AMDEC FMEA…

Traçabilité au sein du logiciel AMDEC

FMEA gère la traçabilité, autrement dit l’historisation, au niveau de chacune des données : on peut ainsi par un simple filtre retrouver à tout moment l’ensemble des informations liées à un acteur, ou à une date. Il est donc ainsi immédiat d’identifier ce qui a été réalisé depuis la réunion ou l’audit précédent par exemple.

Vous pouvez

- savoir par un clic-droit sur chaque cellule qui a modifié son contenu (libellé) et quand,

- accéder à tout l’historique des événements réalisés sur l’étude.

Ces informations de traçabilité sont ensuite exploitées par Storyboard, cette nouvelle fonctionnalité unique sur le marché vous permet d’aller au-delà des indicateurs et reporting avec une approche dynamique : le film de ce qui s’est passé en plus des photos. L’objectif est de disposer d’un visuel pour s’auto-auditer et améliorer les process et bonnes pratiques. Par exemple vous aller pouvoir visualiser l’évolution dans le temps de l’impact des modifications d’exigence en cours de développement.

Quelques fonctionnalités du logiciel d’ AMDEC

- Personnalisation possible des règles du jeu (alertes, liaison gravité et effet…), de l’ergonomie de saisie (vocabulaire, colonnes, aides contextuelles…)

- Personnalisation des supports de communication : indicateurs, Criticité OS/ DS, rapports de synthèse, plan d’actions au format GANTT, gamme d’autocontrôle, fiches de poste, éléments du dossier justificatif de conception, …

- Filtres graphiques & outils de tris, y compris dans les supports de communication de type html : tous les changements intervenus dans l’étude depuis ou à une date donnée, toutes les données spécifiques à un projet, …,

- Représentations graphiques sur toutes les données numériques, diagrammes radar (kiviat),

- Copier / coller avancés (branche d’arborescence et ses tableaux associés), y compris d’une étude à l’autre,

- Multi-tableaux : plusieurs tableaux liés entre eux, et à tous les niveaux de l’arborescence par exemple pour détailler les cotations OS et OS/DS; pour lier AMDEC Process / plan de surveillance / fiche de poste,

- Recherche des causes par diagramme des 5M (Ishikawa – arêtes de poisson),

- Passez de la CAO aux AMDEC, Récupérez les cotes et tolérances de vos plans CAO en point de départ des AMDEC avec Infra CONVERT

- Import Excel pour récupérer vos études existantes,

- Gestion multilangue des données de l’étude. Interface en français, anglais, allemand, espagnol, portugais,…

- Imports / Exports vers Word, Excel, Access ou XML,

- Accès immédiat à la vision du bloc diagramme fonctionnel (BDF) ou du SADT lors de la réalisation des AMDEC Produit, si le logiciel de création des blocs diagrammes fonctionnels Structure est activé,

- Gestion personnalisable des droits et rôles, ce qui permet à chacun de n’accéder qu’aux informations qui le concernent et de restreindre si besoin les possibilités de modification.

- Interfaces possibles avec d’autres logiciels : connecteurs sur devis – à la fois sur les données d’études et sur les bibliothèques.

Le logiciel AMDEC FMEA de Knowllence peut être intégralement personnalisé à vos habitudes de travail ou à vos besoins de consolidation des informations en provenance de différents sites.

Chacun dispose ainsi du point de vue qui le concerne: concepteur, animateur amdec, pilote d’action, simple membre de groupe de travail, manager, etc.

N’hésitez pas à nous consulter !

Notre FAQ Logiciel AMDEC

Pourquoi utiliser un logiciel AMDEC ?

Un logiciel AMDEC automatise et simplifie le processus d'analyse des défaillances tout en facilitant le respect des bonnes pratiques Qualité et la mise en oeuvre des référentiels choisis . Il permet de gagner du temps, de réduire les erreurs humaines, de centraliser les données et de générer des rapports détaillés , de disposer d'indicateurs à jour en permanence. Cela facilite la collaboration entre les équipes et diminue le stress en cas d'audit.

Comment un logiciel AMDEC améliore-t-il la productivité ?

Un logiciel AMDEC améliore la productivité en automatisant les tâches répétitives, en fournissant des modèles prédéfinis, en permettant une collaboration en temps réel et en générant des rapports détaillés en quelques clics. Cela permet aux équipes de se concentrer sur l'analyse et la résolution des problèmes plutôt que sur la gestion des données.

Quel est le prix d'un logiciel AMDEC ?

Le coût d’un logiciel AMDEC dépend de plusieurs paramètres, notamment :

- Le périmètre fonctionnel souhaité : AMDEC produit analyses fonctionnelles, AMDEC process, plan de surveillance, génériques, langues mises à disposition,

- Le ou les référentiels métier retenus : AIAG 4th , automobile AIAG-VDA, aéronautique, etc

- Le nombre d’utilisateurs, le nombre d’instances, parfois le nombre de sites ou l'effectif

- Les besoins éventuels en personnalisation par rapport au logiciel standard : démarche d’évaluation des risques, grilles de cotation, indicateurs, rapport et synthèse, mise en place d’automatismes (envoi de mails, alertes,..)

- Interface/ intégration avec vos systèmes d’informations (MES /SPC, SMQ/SMI, ERP, etc.)

- L’accompagnement souhaité : nombre de sessions de formation, e-learning, récupération de vos études existantes (excel ou autre logiciel), conduite du changement.

- Le type de déploiement web envisagé : SaaS/ Cloud ou hébergé sur vos serveurs (On Premise) et les connecteurs/API à mettre en œuvre

Quels types d'analyses puis-je effectuer avec votre logiciel AMDEC ?

Notre logiciel AMDEC permet d'effectuer notamment l'AMDEC produit, l'AMDEC MSR, l'AMDEC process, l'AMDEC moyen, l'AMDEC système .

Quel est le meilleur logiciel AMDEC ?

Il n’existe pas de « meilleur » logiciel AMDEC universel. Le choix dépend :

• du secteur d’activité (automobile, aéronautique, énergie, domotique, mécatronique, pharmacie, Life Science, etc.),

• des exigences de vos clients / donneurs d’ordre

• des contraintes techniques et réglementaires,

• de la taille de l’organisation : d’un site unique aux grands groupes multinationaux

• de la maturité digitale de l’organisation

• des besoins de capitaliser le savoir-faire de l’entreprise.

Un bon logiciel AMDEC doit être modulaire, interopérable avec l’existant, adaptable aux processus métiers et évolutif dans le temps.

Il est recommandé d’établir un cahier des charges clair et de comparer plusieurs solutions avant de faire son choix.

Pourquoi choisir Robust Engineering Software, le logiciel AMDEC de Knowllence ?

• Ce sont nos clients qui en parlent le mieux : découvrez nos références à travers des avis clients et des vidéos

• Découvrez tous les détails et fonctionnalités sur notre site dédié, ou participez à une démonstration

• Notre solution web est disponible en version standard (clé en main) est développée par une équipe d’ingénieurs informatiques, selon les spécifications réalisées par nos consultants- formateurs métiers, à partir des référentiels AMDEC reconnus au niveau mondial.

• C’est aussi la solution la plus paramétrable du marché capable de répondre à vos attentes spécifiques - n’hésitez pas à nous transmettre votre cahier des charges

• Contactez-nous pour une mise en relation avec l’un de nos experts en digitalisation des évaluations des risques en cliquant ici.